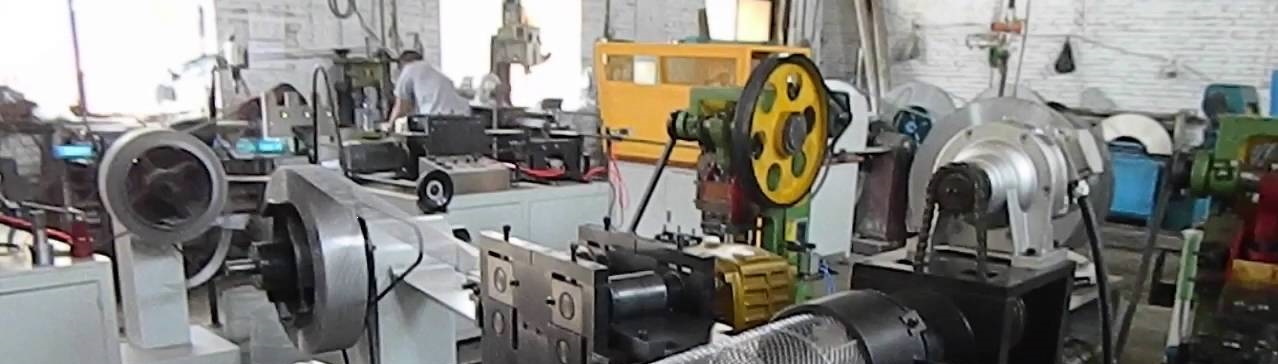

Manufacturing

The latest developments in production machinery are important features in the manufacture of a reliable and cost-effective product. We also believe that people are the Company’s most important asset.

Production units are small and flexible with each section producing a group of filters and each member of staff trained in every aspect of the manufacturing process. Every one of our employees is fully involved and interested in the finishing product.

Staff turn – over is low whilst performance is consistently high – and that’s what shows in the end product. We can create a better product for our customers because we manufacture our filters from basic raw materials instead of prefabricated components. This gives us maximum control over the quality and uniformity of the finished product.

We can select raw materials that reduce waste and save energy, in keeping with our Company’s commitment for respect to the environment.

Full compliance with international OEM requirements concerning Quality Management System. We have successful many-year experience of supplies for the global network of international OEM. Capacities for in-house development and tests of items in accordance with Customer’s requirements. Openness and transparency of the Company, the direction of attention to Customer’s needs, we highly focused on.